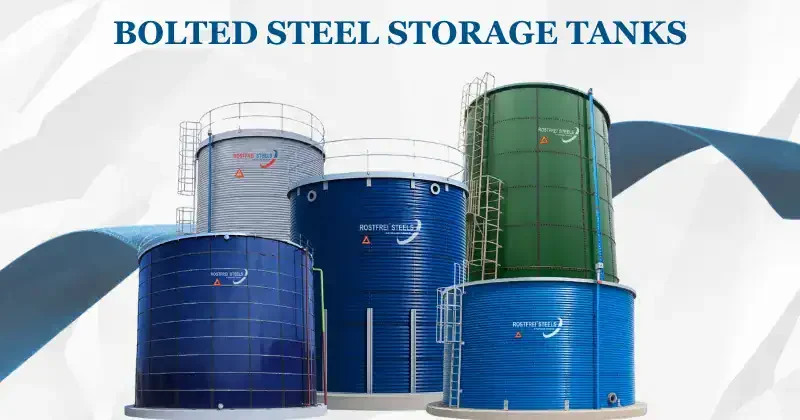

Rostfrei Steels is one of Asia’s largest leading manufacturers of bolted steel tanks engineered for decades of reliability, corrosion-resistant and leak-proof liquid storage solution. Our tanks are designed using globally proven design codes and offers multiple material of construction solution for every industry with specialized corrosion resistant coatings on Fusion Bond Epoxy (FBE) and Glass Fused Steel (GFS) tanks, which ensures strength and durability required for water storage, wastewater treatment plants and other industrial applications.

Our tanks are certified and suitable for potable water storage, fire water reservoirs, wastewater treatment, other industrial liquids, slurries and a wide range of heavy-duty storage applications.

Why Bolted Steel Tanks?

- Quick onsite installation

- Modular design for easy transportation

- No onsite welding

- 100% leak-proof sealing systems

- High corrosion resistance

- Lower cost compared to RCC tanks

- Easy maintenance and repair

Bolted tanks are preferred across industrial, municipal and infrastructure projects due to their reliability, quick installation and cost-efficiency.

What Are GFS & FBE Bolted Steel Storage Tanks?

GFS & FBE bolted tanks are factory-fabricated steel panels that are thermostatically coated, shipped and assembled at site using bolting system and specialized sealants or liner membranes with help of jacks.

This ensures:

- Consistent coating quality

- High structural strength

- Superior corrosion protection

- Zero leakage

- Faster construction timelines

Bolted Steel Storage Tanks Portfolio of Rostfrei Steels

Rostfrei Steels offers a complete range of bolted steel tanks suitable for different environments, industries and applications.

1. Zincalume Steel Tanks (ZA)

(Corrugated Panels with PVC Liner membrane)

Best suited for: Economical water storage solution in non-corrosive environments

Material: Mild Steel corrugated sheets with Zincalume / Galvalume coating (Al 55%, Zn 43.5%, Si 1.5%)

Sheet Thickness: 0.8 mm to 1.2 mm

Coating Thickness: 25–30 micron (150 GSM)

Durability: 25+ years design life, maintenance free up to 3-5 years.

Applications: Clear, raw, fire, agriculture water storage, rural water supply, construction and rainwater harvesting, RO water, DM water storage.

Key Benefits:

- Economical

- Lightweight and quick installation

2. Fusion Bonded Epoxy Tanks – FBEC Patent Technology

(Corrugated Panels with PVC Liner membrane)

Best suited for: Water storage in mildly corrosive environments

Material: Mild Steel sheets are coated with Resicoat Epoxy, pre heated and post baked at approximately 150-250°C

Sheet Thickness: 0.8–2.5 mm

Coating Thickness: 100–150 micron

Durability: 25+ years design life, maintenance free up to 10-15 years.

Liner: PVC-based

Applications: Industrial water, raw, fire, agriculture water storage, rural water supply, construction and rainwater harvesting, RO water, DM water storage, in corrosive atmospheres.

Key Benefits:

- Patent Technology

- Suitable for corrosive environments

- Quick Installation

3. Fusion Bonded Epoxy Tanks – FBE

(Plain Panels with Sealant)

Best suited for: Potable / Drinking water, STP, Industrial corrosive liquids, RO reject, Biogas plants, Slurry storage.

Material: Mild Steel with Resicoat Epoxy, pre heated and post baked at 250–300°C

Coating Thickness: 150-250 micron

Durability: 30+ years of design life, maintenance free up to 20 years.

Certifications: NSF-61 certified for drinking water

Applications: Drinking water storage, fire – fighting systems, process water, light wastewater

Key Benefits:

- Suitable for potable water

- High corrosion resistance

- Minimal maintenance requirement

4. Glass Fused Steel Tanks (GFS)

Best suited for: Potable water, ETPs & STPs, Biogas Digester/Fermenters, Slurry storage, other high TDS & Industrial corrosive liquids.

Material: Enamel Grade Mild Steel sheets coated and baked at 700–900°C

Coating Thickness: 150–350+ micron

Durability: 30+ years of design life, maintenance free up to 20 years

Certifications: NSF-61 certified, FM Approved (Fire Water Tanks)

Applications: Wastewater, effluents, sludge, STP/ETP tanks, corrosive liquid storage, desalination, coastal and marine environments

Key Benefits:

- Longest durability

- Zero maintenance for up to 20 years

- Superior performance against corrosion, abrasion, chemicals and UV exposure

Selection Guide: Which Tank is Right for You?

- ZA: Economical solution for clear water storage

- FBEC: Industrial water and moderate corrosive environments

- FBE: Drinking water, fire water and industrial liquid storage for high corrosive environments

- GFS: Potable water, fire water, wastewater treatment plants for coastal and high-corrosion environments

For detailed recommendations, our engineering team provides free technical consultation.

Parameter | ZA | FBEC | FBE | GFS |

Panel Type | Corrugated | Corrugated | Plain | Plain |

Coating | Zincalume | Epoxy + PVC Liner | Epoxy + Sealant | Glass + Sealant |

Coating Thickness | 25–30 micron | 100–150 micron | 150–250 micron | 300–350+ micron |

Sheet Thickness range | 0.8–1.2 mm | 0.8–2.5 mm | 2–14 mm | 2–12 mm |

Approx Durability. | 5–10 years | 20–30 years | 20–30 years | 30–50 years |

Certifications | None | Patent | NSF-61 | NSF-61 / FM |

Industries and Applications- Bolted Steel Storage Tanks

- Raw/ Fire/ Soft Water Storage

- Treated Water Storage

- Rainwater Storage

- DM Water Storage

- Effluent Water Storage (ETP)

- Sewage Water Storage (STP)

- Process Water Storage

- Process Water Storage

- Drinking Water

- Desalination Plant

- Edible Oil Storage

- Textile Industry

- Power Industry

- Paper Industry

- Mining Industry

- Foods/Beverages Industry

- Automobile Industry

- Water Industry

- Institute/ Commercial Complex

- Dairy Industry

- Energy Industry

- Pharmaceuticals Industry

- Oil Industry

Engineering, Design and Installation of Bolted Storage Tanks

All tanks are designed and manufactured as per globally accepted standards:

- AWWA D-103

- AS-2304

- NSF-61

- FM Approval Standards

Our scope includes structural design, sharing GA drawings for client approvals, indicative foundation details as per tank requirement, inhouse QC checks, onsite installation, accessories fixing, roof structures and final water testing of tank before handover.

Why Choose Rostfrei Steels?

- One of India’s largest bolted tank manufacturers

- 20+ years of industry experience

- More than 9,000+ installations across 30+ countries

- In-house engineering, fabrication and installation & commissioning teams

- German and American coating technology

- Fast delivery and reliable installation support

- Proven and certified leak-proof performance

Our tanks are trusted by government bodies, EPC companies, industrial clients, infrastructure developers and turnkey contractors worldwide.

How We Can Help

For design support, cost calculation, BOQ, drawings or pricing, contact our technical team.

We provide complete consultation and customised solutions for all types of liquid storage requirements.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.