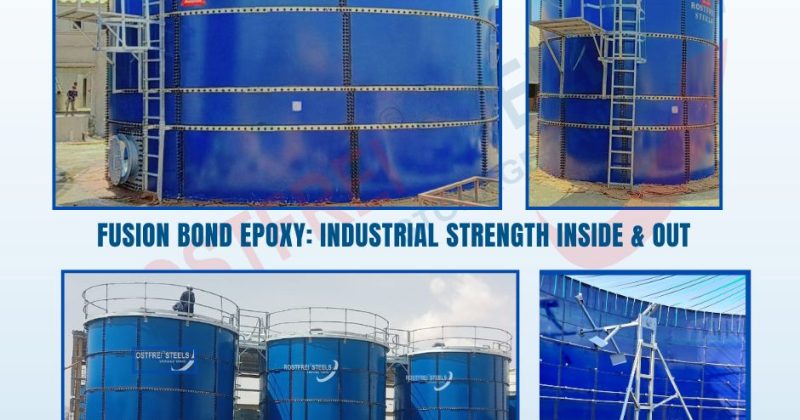

Fusion Bond Epoxy Tanks: Advanced Storage for Demanding Applications

When it comes to industrial liquid storage, not all tanks are designed to withstand the test of time and extreme conditions. In such industries, where tanks are constantly exposed to corrosive liquids, fluctuating temperatures, and abrasive environments, standard hand-painted coatings are often found to fail. It is in these scenarios that Fusion Bond Epoxy (FBE) coated tanks are distinguished from others.

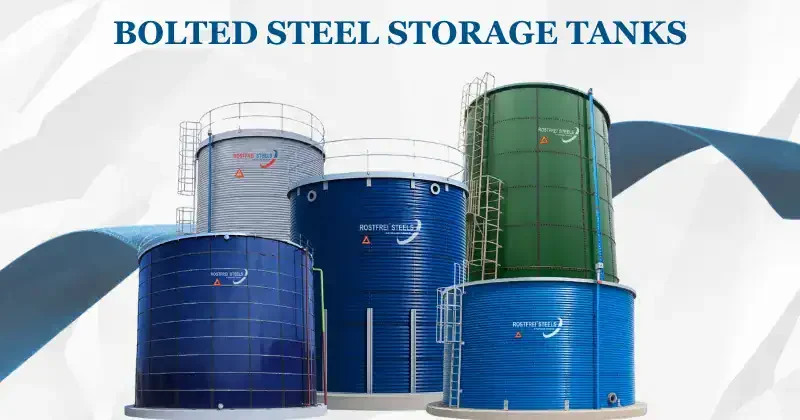

Moreover, these tanks are engineered to combine the structural strength of bolted steel with the corrosion resistance provided by Resicoat epoxy coating, and are widely recognized as one of the most reliable solutions for harsh industrial and environmental applications.

What Makes Fusion Bond Epoxy Tanks Different?

Resicoat Epoxy is a thermosetting epoxy powder that is electrostatically applied to preheated steel surfaces. Once cured, a cross-linked, holiday-free, corrosion-resistant barrier is formed, ensuring the steel tank is protected from aggressive agents.

Key Benefits of FBE Coating:

- Exceptional corrosion resistance in harsh liquids and saline conditions

- Strong adhesion to steel with minimal risk of delamination

- High dielectric strength, reducing risk of under-film corrosion

- Resilience in fluctuating temperatures and harsh UV exposure

- Field-repairable with help of tools and sealant

Learn more about Fusion Bond Resicoat Epoxy Coatings

Superior Performance in Harsh Environments & Coastal Areas FBE tanks are designed to perform where conventional coatings and paints fail.

1. Coastal & Marine Environments

Salt-laden air and brackish water are notorious for corroding steel structures. FBE tanks provide long-term resistance to chloride attack, making them ideal for desalination plants, ports, and offshore facilities.

2. Chemical & Petrochemical Storage

Industries dealing with acids, alkalis, and industrial solvents require tanks that don’t leach, degrade, or fail under chemical exposure. FBE offers a reliable lining for a broad range of industrial chemicals with PH ranging from 4-11.

3. Power Generation & Cooling Systems

In thermal and nuclear plants, tanks are often exposed to high temperatures, aggressive water chemistry, and scaling risks. As a result, FBE-coated corrugated tanks ensure long-term longevity and require minimal maintenance, even under such demanding conditions.

4. Mining & Mineral Processing

From water, wastewater, effluents, digestate, and mild acids and alkalis (e.g., dilute HCl, H₂SO₄ <10–20%, sodium hydroxide <20–25%) to storage for process water and slurry handling, mining environments are particularly harsh. Therefore, FBE tanks are able to withstand abrasive media while also reducing downtime caused by corrosion damage.

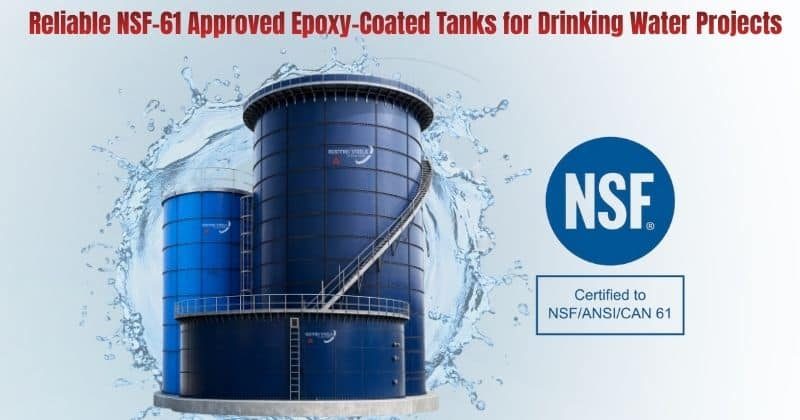

5. Drinking Water & Safety

NSF 61 approved FBE-coated tanks are increasingly used for storing drinking water because they guarantee purity with best standards.

Why Choose Fusion Bond Epoxy Tanks Over Alternatives?

- FBE vs. on site Hand Painted epoxy Tanks: Paint coatings degrade faster under UV and harsh liquid attack; FBE lasts longer.

- FBE vs. Stainless Steel: While stainless offers corrosion resistance, it comes at a much higher cost. FBE is more cost-effective with design life of 30+ years.

Applications Across Industries

- Sewage Treatment (STP) Tanks: Resistant to chemicals and sludge

- Biogas Digester, Slurry Tanks, Gas Holders.

- Water & Wastewater Treatment (WWTP) Tanks: Long-term durability against treated and raw water

- Zero Liquid Discharge (ZLD) Systems : Handles concentrated streams of salts and chemicals

- Desalination & Condensate Water Tanks : Ideal for saline or brackish water environments

- Irrigation & Potable Water Tanks: Ensures safe water storage

- RO Water & RO Reject Water Tanks – Protects against chemical and mineral attack

- Drinking Water Tanks (NSF 61 certified tank/liner) : Safe for human consumption

- Rainwater Collection Tanks: Corrosion-resistant for seasonal storage

- Fire Water Tanks : FM-approved for emergency reliability

- Clear Water & Raw Water Tanks : Suitable for industrial and municipal applications

- DM Water & Soft Water Tanks : Protects high-purity water from contamination

Fusion Bond Epoxy coated tanks are not just storage solutions in fact, they are long-term assets that deliver performance in the toughest environments. By combining strength, modularity, and corrosion resistance, they therefore ensure superior reliability, lower life-cycle costs, and safety compliance.

Consequently, if your industry demands tanks that last in harsh conditions, Fusion Bond Epoxy tanks remain the ideal solution.

Frequently Asked Questions (FAQs) – Fusion Bond Epoxy Tanks

What are Fusion Bond Epoxy (FBE) tanks?

Fusion Bond Epoxy tanks are steel storage tanks coated internally & externally with a thermosetting resicoat epoxy. This coating provides superior corrosion resistance, making them ideal for harsh environments and industrial applications.

What types of liquids can FBE tanks store?

FBE tanks are suitable for a wide range of liquids. For instance, they can store potable water, RO water, sewage, desalinated water, irrigation water, drinking/potable water, fire water, DM water, soft water, and various industrial chemicals. Moreover, they are widely used for ZLD systems and condensate water storage, ensuring reliable performance across diverse industrial applications.

Are FBE tanks safe for drinking water?

Yes, FBE tanks can be NSF 61 certified, making them safe for storing drinking water and potable applications.

Can FBE tanks be used in marine or coastal environments?

Absolutely. The epoxy coating protects the steel from salt-laden air and brackish water, making them ideal for desalination plants, ports, and offshore facilities.

How do FBE tanks compare to glass-lined or painted tanks?

Unlike glass-lined tanks, FBE coatings don’t spall or crack around bolt holes, and they last longer than paint coatings which degrade under UV or chemical exposure. FBE also offers cost-effective corrosion protection compared to stainless steel

Can FBE tanks handle industrial chemicals?

Yes, indeed, they are suitable for mild acids, alkalis, solvents, and other industrial chemicals. Therefore, they are considered ideal for chemical plants, mining operations, fertilizer storage, and various process industries.

What maintenance is required for FBE-coated tanks?

FBE tanks are low-maintenance due to their durable lining. Minor repairs can be done on-site if needed, and regular inspection ensures long-term reliability.