Across the United States, from the grain belts of Iowa to the industrial corridors of Texas, an increasing number of facilities are facing the same problem aging, rusted, high-maintenance silos. Many welded steel structures installed decades ago are now failing due to corrosion, metal fatigue, and outdated coating technologies. This has led industries to actively search for storage systems that are durable, corrosion-resistant, and designed for long-term performance. Modern bolted steel silos have emerged as the preferred solution because they offer significantly higher durability, easier installation, and long-term cost efficiency compared to older welded units. As industries modernize, bolted steel silos are becoming the backbone of reliable storage across the USA.

What Makes Today’s Bolted Steel Silos Ideal for U.S. Applications?

Contemporary bolted silos are engineered to meet demanding storage standards. They use high-strength steel panels, precision-built modular components, and advanced protective coatings to ensure consistent performance in a wide range of environments. Their design allows for fast transportation, simplified assembly, and efficient long-term maintenance. In addition, their corrosion-resistant surfaces meet modern food-safety and industrial requirements, making them suitable for grains, animal feed, ingredients, water, and various chemicals used throughout American industries. This is exactly why the USA needs modern silos advanced, durable, and engineered for long-term reliability.

How Does U.S. Climate Influence Silo Longevity?

The United States experiences some of the world’s most diverse weather conditions, and each climate zone affects silo performance differently:

- Northern states endure extended sub-freezing temperatures that can cause welded seams to shrink or fracture.

- Midwestern regions require structures capable of bearing the high internal pressures associated with large harvests.

- Humid southeastern states experience rapid rust formation on unprotected steel.

- Western and coastal areas face intense heat, UV exposure, and salt-laden winds that accelerate surface corrosion.

Bolted silos equipped with specialized coatings and flexible joint systems are specifically engineered to tolerate these climatic extremes far better than traditional welded units.

Why Do Older Silos in the U.S. Rust So Quickly?

Many existing silos were built using mild steel with basic paint finishes that gradually degrade under long-term weather exposure. Welded joints naturally rigid and stress-prone tend to corrode first. Decades of rain, ambient moisture, freeze–thaw cycles, and salt-rich coastal air eventually lead to thinning steel walls, leakage, contamination risks, and reduced structural reliability. Frequent repainting and patch repairs become inevitable. Modern bolted silos address these issues through advanced coating technologies such as Galvalume, Zincalume, and Glass-Fused-to-Steel highlighting exactly why the USA needs modern silos that are engineered for long-term durability and superior corrosion protection.

How Do Corrosion-Resistant Coatings Benefit U.S. Industries?

Today’s high-performance coatings significantly extend the service life of steel silos. Zinc-aluminum alloys such as Zincalume and Galvalume offer several times the corrosion resistance of conventional galvanized steel. Glass-Fused-to-Steel creates a highly durable surface that supports long-term rust protection, often exceeding three decades of service.

These coatings are especially valuable in humid, coastal, or industrial regions of the U.S., where traditional steel systems degrade quickly. They support sanitary storage, minimize maintenance needs, and provide consistent performance under harsh environmental conditions.

Why Are Modular and Prefabricated Silos Easy to Install Across the U.S.?

Bolted silos are manufactured in controlled factory environments and delivered as lightweight modular panels. This construction method allows for economical transportation and rapid installation whether the site is a Midwestern farm, a Southwestern industrial facility, or a remote rural property.

Because bolted systems do not require on-site welding, labor demands are significantly lower an advantage in states where labor costs are high. Their modular structure also allows for future capacity expansion by simply adding additional rings

Why Are U.S. Companies Turning Toward Low-Maintenance, Long-Life Silos?

Modern industries prioritize efficiency, operational safety, and long-term cost reduction. Bolted silos align with all these goals. Their corrosion-resistant coatings minimize routine maintenance, while their engineered structure supports decades of reliable performance.

Agricultural and food-processing sectors benefit from cleaner, safer storage, while industrial users appreciate the reduced operational downtime and long service life

How Do Modern Silos Improve Return on Investment for U.S. Farmers and Industries?

Upgrading to bolted steel silos produces notable financial advantages:

- Longer service life reduces replacement frequency.

- Corrosion-resistant coatings lower maintenance and repair costs.

- Stronger load-bearing design enables safer storage during peak seasons.

- Faster installation accelerates operational start-up.

- Enhanced hygiene reduces spoilage and contamination losses.

Collectively, these benefits generate a strong return on investment within just a few years.

Why Are Modern Steel Silos Better Suited to U.S. Climate Conditions?

Engineered coatings prevent rust formation even in extreme environmental conditions, while flexible bolted joints manage thermal expansion more effectively than welded surfaces. This combination makes modern silos appropriate for cold northern winters, hot southwestern climates, and humid southeastern regions.

Which Silos Work Best in High-Humidity States?

For locations such as Florida, Louisiana, and Alabama, silos with Glass-Fused-to-Steel or Zincalume coatings are ideal. These materials resist moisture-driven corrosion and help prevent mold growth inside the storage environment.

Are Modern Silos Suitable for Cold Regions Like Minnesota and Michigan?

Yes. In extremely cold regions, welded units often crack due to temperature-related expansion and contraction. Bolted silos, designed with flexible connections and corrosion-resistant coatings, maintain structural integrity under severe winter conditions.

What Silos Best Support Grain Storage in the Midwest?

Midwestern operations require high-strength structures capable of storing large grain volumes. Bolted silos made with high-tensile steel and food-grade internal coatings deliver both the durability and hygiene required for safe and efficient grain storage.

Why Do Older American Silos Rust More Quickly?

Traditional mild-steel silos rely on painted surfaces that degrade over time. Moisture infiltration at welded seams accelerates corrosion, leading to structural weakening and material loss. Modern coatings and bolted construction help prevent these long-term issues.

Are Modern Silos Suitable for Coastal States Like California and New Jersey?

Yes. Modern coatings such as Zincalume and Glass-Fused-to-Steel provide strong resistance to saline coastal winds, ensuring long life and reliable performance in marine environments.

How Long Do Modern Bolted Steel Silos Last in the U.S.?

With advanced coatings and proper installation, modern bolted steel silos typically provide 30 to 40 years of dependable service with minimal upkeep.

Which Silos Are Best for Water and Liquid Storage?

For water treatment systems, industrial liquids, and fire-protection applications, bolted tanks with Glass-Fused-to-Steel or premium epoxy coatings offer the durability and leak resistance required by U.S. industrial standards.

Can Steel Silos Be Installed Quickly in Remote Locations?

Yes. Their modular, low-weight design enables rapid assembly in locations with limited equipment access, including rural farms, mountain areas, and isolated industrial zones.

What Silos Are Best for High-Temperature States Like Arizona and Texas?

For hot climates, silos with UV-stable and heat-resistant coatings such as Zincalume and GFS perform exceptionally well. These coatings protect against thermal degradation and maintain structural stability under intense sunlight.

How Can U.S. Industries Reduce Silo Maintenance Costs?

The most effective strategy is to invest in corrosion-resistant bolted silos. Their protective coatings eliminate the need for continuous repainting, surface restoration, and structural repairs, delivering significant long-term cost savings.

How Do Modern Silos Improve Food-Safety Standards?

Food-grade internal coatings meet U.S. regulatory guidelines and prevent issues such as microbial contamination, condensation, and chemical reactions with stored materials. This ensures clean, safe storage for grains, ingredients, and feed products.

Are Modern Steel Silos a Good Replacement for Old Rusted Structures?

Yes. Their advanced coatings, flexible design, and modular construction make them significantly more durable and easier to maintain than aging welded silos.

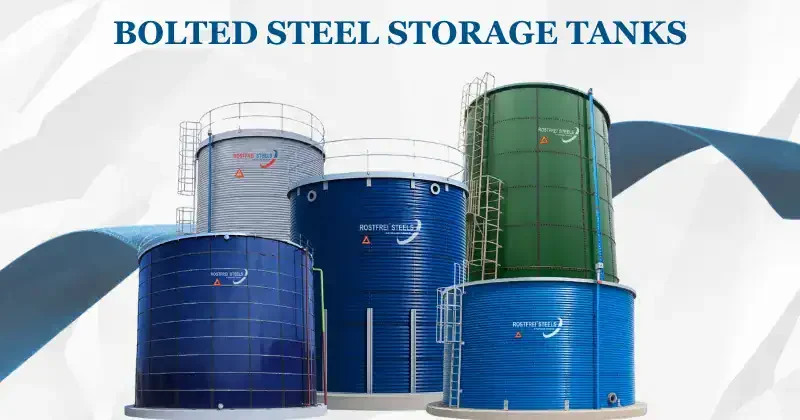

Which Manufacturers Supply Corrosion-Resistant Silos to the U.S. Market?

Several modern suppliers such as Rostfrei Steels provide certified, corrosion-resistant bolted silos for agricultural, industrial, and municipal applications across the United States.

How Can U.S. Companies Maximize Long-Term ROI from Silo Investments?

By selecting corrosion-resistant materials, ensuring proper installation, and choosing modular designs that allow expansion, companies can minimize maintenance costs, improve operational safety, and secure long-term value.

As U.S. industries continue upgrading their storage infrastructure, long-life bolted steel silos have emerged as a preferred option due to their durability, corrosion resistance, and ease of installation. Equipped with advanced coatings and modular engineering, they provide reliable performance across diverse American climates. For businesses seeking future-ready and cost-effective storage solutions, modern bolted silos offer a dependable foundation for long-term operations.